Loading... Please wait...

Loading... Please wait...Free Shipping on orders over $400

Categories

Blog - surgical scalpel

Surgical Blades: Which Scalpels Are Right for Your Operating Room?

Posted on 11/03/2018 10:18:36

Choosing the right types of surgical blades for the operating teams at your hospital or surgical center can be a daunting challenge. Surgical blades vary by size and shape, while some models are manufactured for specific surgical procedures. After assessing your current inventory, you’ll want to research and consider the following before making any new surgical blade purchases:

Which Surgical Blades are Right for Your Operating Room?

- Single-Use or Reusable Blades

- Materials

- Blade Shape

- Edge, Spine and Slot

Surgical blades are vitally important and must be held to the highest standards of excellence. These blades require a tremendous amount of sharpness in order to effectively cut human tissue.

In an operating room setting, the right surgical tools, including everything from instruments to surgical lighting, can be just as critical as the expertise and techniques of your surgical teams. Having the right surgical scalpel blades for the specific procedures can make a huge difference in the surgical team’s success and ensures the best possible outcome for patients. This is particularly true for minimally invasive surgery, as well as ophthalmic, cardiovascular and endoscopic procedures. The precision of the surgical knife blades plays a critical role in any successful surgery.

Depending on the type of surgery or procedure, your team’s collective surgical expertise, and the physical layout of the operating room, different types of blades have different advantages. As you research how best to stock your practice, keep these points in mind when purchasing your surgical blades.

Why Are Surgical Blades Numbered?

Every surgical blade is numbered to indicate its size and its shape – think of it as a shorthand code for labeling a blade's characteristics.

A surgical scalpel typically consists of two complementary parts: the handle and the blade. You’ll hear the handle referred to as a “B.P. handle,” named after Charles Russell Brand and Morgan Parker, who patented the two-piece design in 1915. They realized that using heat during the sterilization process actually dulled the blades. So, they also developed a cold sterilization process that would protect the sharpness of the blade. Genius!

The numbering system dates back to Morgan Parker, who numbered the handles from 1-9 and assigned the surgical blades a number from 10-20. The system became widely accepted in the medical community. Today, the same numbering system is used, with a few exceptions due to patent expirations.

Surgical Blade Handles

Surgical blades are often purchased separately from the surgical blade handle. The surgeon selects the best surgical blade handle for the procedure. Surgical blade handles vary in size, weight, and length to provide the surgeon with the optimal precision, balance and visibility. Surgical blade handles come in different versions ranging from #3 to #9. The #3 and #4 have a long, flat handle. The #5, #6, and #8 blade handles have a wider base. The #7 is shaped much like a writing pen-slender and rounded at the front and flat at the back. The #9 handle is longer and slender. Surgical blades come in complementary sizes, each designed to fit exclusively on a specific handle size.

Surgical Blades

Surgical blades come in sterile packaging and the number on a surgical blade communicates both its size and its shape. Some common types and numbers of blades include the following:

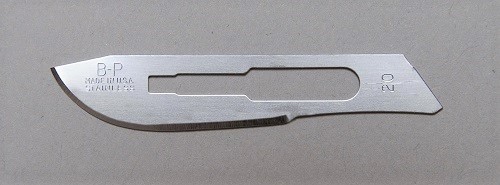

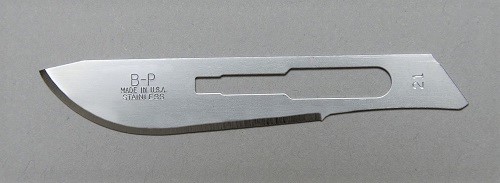

The #10 – A large curved cutting edge, which represents a more traditional blade shape. It is used for cutting soft tissue, typically with large incisions.

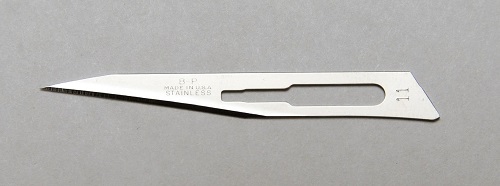

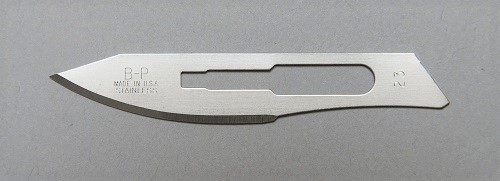

The #11 – A long, triangular blade with the hypotenuse as its sharpest edge. Because of its pointed tip, it is typically used for stabbing incisions and/or short, precise cuts that are shallow.

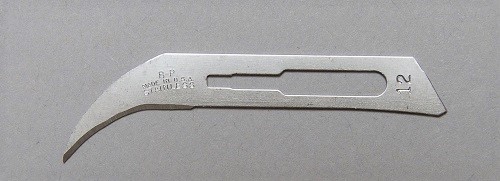

The #12 – A small, pointed, crescent-shaped blade used typically as a suture cutter. It is most sharp on the inside edge of its curve.

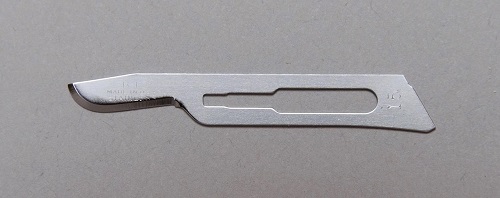

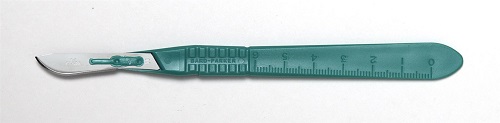

The #15 – Ideal for making short, precise incisions because of its small, curved cutting edge.

The #20 - A large curved blade commonly used for cutting tissue and other procedures that require a puncture or cut.

The #21 –Similar to the #20, it features a large curved blade commonly used for cutting tissue and other procedures that require a puncture or cut.

The #22 – Essentially a larger version of the #10, it has a flat, unsharpened back edge and a short, curved cutting edge. These blades are best for creating large incisions, often through thick skin.

The #23 – A large blade that is slightly narrower than the #21 and #21. It also has a pointier tip.

There are several important factors to consider as you research the best surgical blades for your team. Let’s take a closer look at the different types of blades you will likely need for your operating room.

Single-Use or Reusable Blades

Surgical scalpels are available in either single-use or reusable versions. Reusable blades are permanently attached to the handle and must be sharpened consistently. Single-use blades are designed to lock onto a scalpel handle and are easily removable. There are also disposable surgical scalpels which typically have plastic handles and an extensible blade. These can be used only once before the entire instrument is discarded.

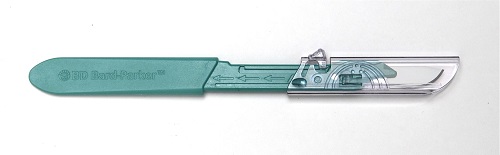

You might also want to consider safety scalpels, which come with a special covering around the surgical blade that protects it until it’s used. The use of safety scalpels has been shown to help prevent accidental injuries caused by inadvertent contact with the blade.

Surgical Blade Materials

Medical experts frequently assert that the making of a surgical blade lies in the quality of the material used to produce it, along with the technology behind grinding the blade’s cutting edge. Silver was historically the material of choice for surgical scalpels, but today, surgical scalpel blades are usually made from stainless steel, tempered steel or high carbon steel. Ceramic, titanium, diamond, sapphire, and obsidian are other less common options.

Sometimes the procedure being performed dictates the surgical blade material that should be used. For example, when performing MRI-guided procedures, an operating team cannot use steel surgical blades, which would be drawn to the magnets and potentially cause image artifacts.

Overwhelmingly, most surgeons prefer steel surgical equipment. Most scalpel blades, surgical scissors, and forceps are made from stainless steel since it tends to resist rust and is more cost-effective. Many surgeons also report a sense of tactile feedback with a steel blade, which can be especially helpful for less experienced surgeons, or even surgical residents. In fact, some experts claim that surgical steel knife blades offer the most precision and durability.

Ceramic blades are a promising newcomer to the surgical blade market, but there is still room for improvement when it comes to durability. These are extremely sharp blades, known for their non-magnetic and non-corrosive properties, though they are not currently recommended for procedures that could result in forceful pressure to the blade.

Blade Shape

Fun fact: Hippocrates was actually the first physician to describe a surgical blade. Interesting, these medical instruments were essentially the same shape back then as they are today. However, there are important differences in the shape of the blade, and you can choose the shape best optimized for your desired procedure.

The most common blade shape is the #10. It’s often used for making small incisions in muscle and skin. Typical applications might include inguinal hernia repair or opening the bronchus during thoracic surgery.

In contrast, the #11 blade is more elongated, with a triangular blade shape and pointed tip. This shape lends itself better to stabbing incisions, such as those needed for opening coronary arteries or the aorta.

The #15 version has a small, curved cutting edge and is typically used to make short, precise cuts. This blade is typically used for procedures such as opening coronary arteries or excising a skin lesion.

Edge, Spine and Slot

Other specifications to consider when buying surgical blades relate to the shape and the finish of the cutting edge. To get started here is some basic terminology used to reference the different types of cutting edges.

Edge

A scalpel blade’s edge is its actual sharp cutting surface, which serves as an important component of the surgeon’s tactile feel. The better the tactile feel, the more control the surgeon has, resulting in more consistent and more precise incisions.

An open edge describes a surgical blade ground on both sides, but only finished on one. This type of knife blade comes with microscopic teeth along the blade’s cutting edge, which gives a surgeon a consistent feel while making an incision. Open-edge blades tend to be more durable and hold their edges longer.

In contrast, closed-edge blades are ground and finished on both sides. Their edges are more closely akin to razor blades, which have very high initial sharpness, but they also can lose their performance edge very quickly.

Some medical equipment manufacturers today use processes and techniques such as electrochemical deburring and laser cutting which allow for the smoothest and sharpest precision knife blades in history. The sharper and smoother the blade, the less drag and tissue trauma will occur.

Spine

The spine of the surgical knife is its unsharpened, ridged edge.

Slot

The most typical surgical scalpel blade is the replaceable version. Since it isn’t permanently attached, it features a key-like slot at an angled base that firmly snaps the scalpel blade into the handle. A surgeon can then “arm” or “disarm” the scalpel simply by moving the end of the handle in or out of the slot.

Knowing this terminology, along with feedback from your surgical team, can help you make better, more informed choices about how to supply your practice.

Which Type of Metal is Best?

This question is best answered by the surgical team, depending on the type of procedures they perform and the surgical team’s tactile sensitivity. Whichever metal you choose, you’ll want to do your research to make sure it’s corrosion-resistant, offers a high degree of strength, and is shock-resistant. Depending on the procedure, you may also need to purchase a blade that is non-magnetic.

When considering carbon steel versus stainless steel, there are a few things you’ll want to keep in mind. For example, a stainless steel surgical blade typically resists corrosion much better than a carbon steel surgical blade. In fact, carbon steel blades have been known to rust almost immediately when they come into contact with saline, while stainless steel blades remain uncorroded. If you know your team may be making multiple incisions in moist conditions, the stainless steel blade may be the better choice. Carbon steel, however, usually has better initial sharpness and durability.

Various coatings are also available to further strengthen surgical blades. These coatings come in silicone, perylene, or other materials that can help augment the corrosion and wear-resistance of surgical blades.

Purchasing Surgical Blades for Your Medical Facility

With the right research and preparation, you can make sure that your surgical team is well-armed for success and positive outcomes for your patients. Overall, purchasing the best quality surgical blades can drive your team’s productivity and ensure high quality patient care, all while providing cost savings and promoting surgeon satisfaction. The right surgical instruments, surgical lighting, and medical devices all play an important role in the success of your surgical team.

Purchasing medical products can be a challenging task. If you don’t know how to get started or where to buy surgical blades, USA Medical and Surgical Supplies is here to help. We carry a wide range of medical equipment including surgical blades, disposable scalpels and surgical blade handles to meet your needs. Our team has decades of experience with medical supplies and equipment. Please contact us if you have any questions about the best surgical products for your practice. Call us today at 1-866-561-2380 or email us at Contact form.